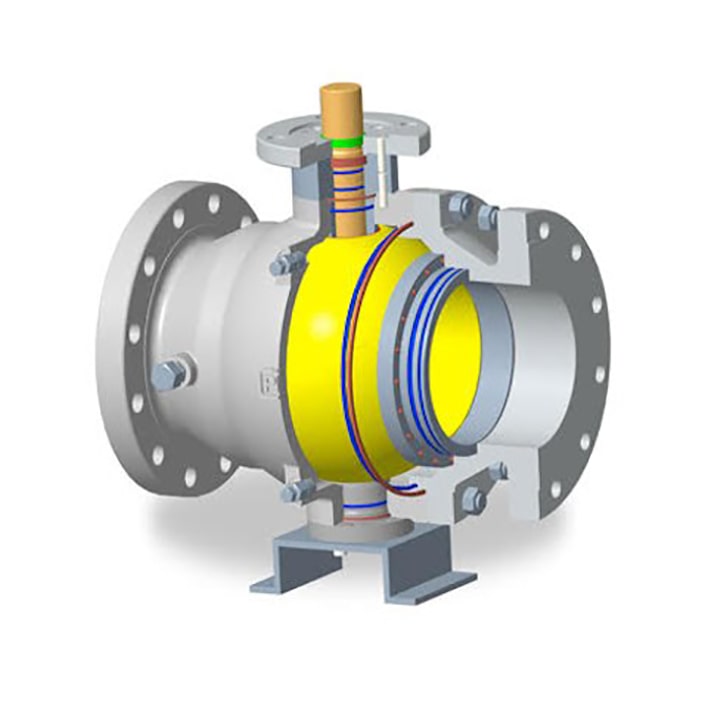

Trunnion Mounted Ball Valve

Trunnion mounted ball valves are designed for upstream sealing. The load generated by the line fluid on ball is absorbed by the trunnion bearings and is directly transmitted to the valve body, and the upstream seat driven by medium pressure drifts towards the ball to create reliable sealing. The seat design has a built-in automatic cavity relief mechanism.

Trunnion mounted ball valves have a bottom entry stem design, where the stem is inserted from inside the body. The higher the line pressure, the tighter the seal.

Features

- Bolted Body – Two Piece/Three Piece and Fully Welded

- Bore Type – Reduced Bore and Full Bore

| Technical Table | |

| Size | 2” to 60“(DN 50 to DN 1500) |

| Pressure Rating | ASME CL150, CL300, CL600, CL900, CL1500, CL2500 |

| Materials | Carbon Steel, Low Temperature Carbon Steel, Stainless Steel, Duplex Stainless Steel, Super Duplex Stainless Steel, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconel Etc. |

| Seating | Soft Seated (PTFE/RPTFE /PEEK/NYLON/DEVLON) and Metal Seated |

| End Connection | Flanged FF/RF/RTJ, BW Ends |

| Operator / Actuator | Lever/Wrench, Gear, Actuator (Pneumatic, Hydraulic, Electric, Motorized, Electro-Hydraulic, Gas over Oil) |

| Standards | ·

· Design – ASME B16.34/BS5351 · Face to Face – ASME B16.10 · End Flange – ASME B16.5 · BW End – ASME B16.25 · Test – API598/API6D · Fire Safe Test – API607/API6FA · Special – NACE MR-01-75 |