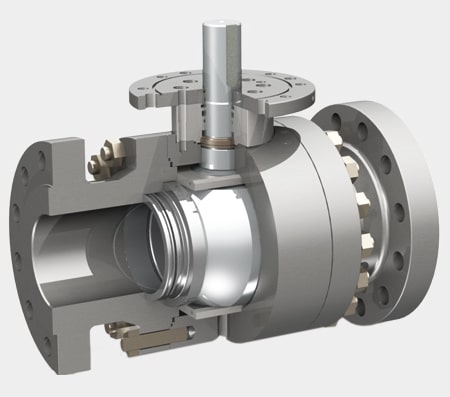

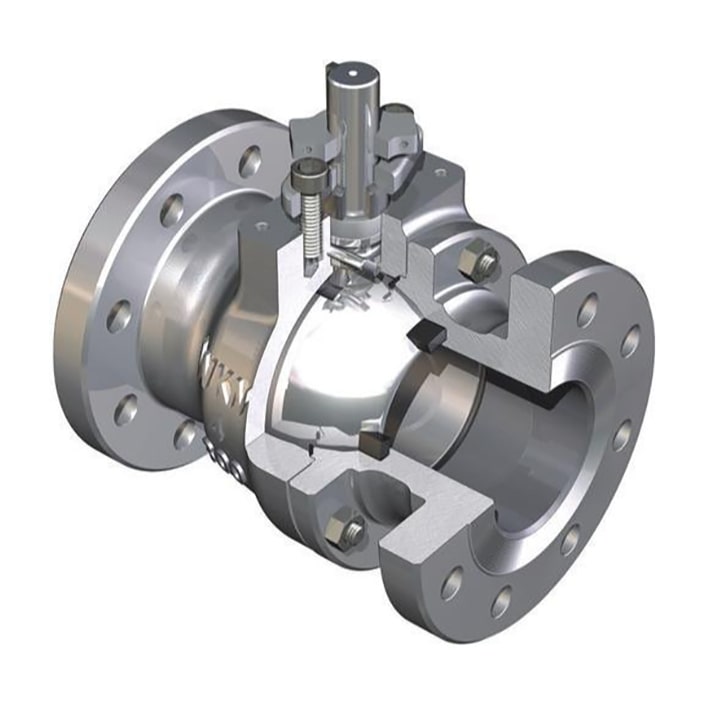

Floating Ball Valve

A floating ball valve is a valve with its ball floating (not fixed by a trunnion) inside the valve body, it drifts toward to the downstream side and tightly pushes against the seat under the medium pressure to ensure sealing reliability. The floating ball valve has simple structure, good sealing performance but the seat material is required to withstand the workload since the sealing pressure is bared by the seat ring. Due to unavailability of high performance seat material, floating ball valve is mainly used in middle or low pressure application. Available in One Piece, Two Piece, Three Piece, Fully Welded designs.

| Technical Table | |

| Size | ½” up to 10“(DN 15 up to DN 250) |

| Pressure Rating | ASME CL150 to CL2500

· ½’’ to 10’’ – 150# · ½’’ to 8’’ – 300# · ½’’ to 4’’ – 600# · ½’’ to 1 ½’’ – 900#, 1500# & 2500# |

| Materials | Carbon Steel, Low Temperature Carbon Steel, Stainless Steel, Duplex Stainless Steel, Super Duplex Stainless Steel, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconel Etc. |

| Seating | Soft Seated (PTFE/RPTFE /PEEK/NYLON/DEVLON) and Metal Seated |

| End Connection | Flanged RF/RTJ, BW, FNPT & SW Ends |

| Operator / Actuator | Lever, Gear, Actuator (Pneumatic, Hydraulic, Motorized, Electro-Hydraulic) |

| Standards | ·

· Design – ASME B16.34/BS5351 · Face to Face – ASME B16.10 · End Flange – ASME B16.5 · BW End – ASME B16.25 · Test – API598/API6D · Fire Safe Test – API607/API6FA · Special – NACE MR-01-75 |