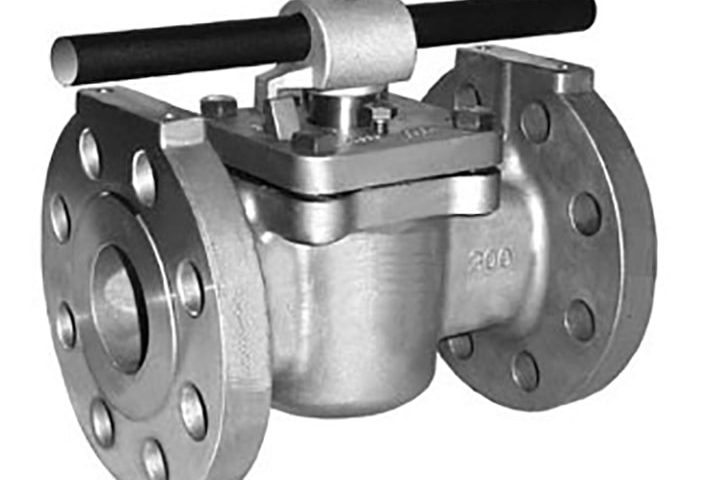

PTFE Sleeved Plug Valve

Sleeved Plug valves are robust in construction and easy In-Line maintainability. These valves are non-lubricated quarter-turn valves that achieve sealing through the use of a compressible sleeve as a sealing member. In many applications they operate virtually maintenance free for decades. Sleeved plug valves are used for on/off and throttling service in demanding process applications with media temperatures ranging from -20°F to 600°F. These valves are used in various industries such as petroleum, chemical industry, pharmacy, chemical fertilizer, electric power industry etc.

These valves are Bi-directional flow, simple actuation, lightweight, compact design, and multiport configurations, all facilitate for improved system design. The inert PTFE sleeve completely surrounds the plug. The sleeve provides a large, circumferential sealing surface from port to port. Open, closed, or rotating, the seal is assured. As the plug rotates, the 360° port lips provide a self-cleaning action to remove scaling and adhering media.

| Technical Table | |

| Design Standard | API 6A, ASME VIII, API 6FA |

| Pressure/Temperature Chart | ASME B16.34 |

| Face to face Dimension | API 6D, ASME B16.10, |

| Testing Standard | API 6A / ISO 5208 |

| Flange Details | ASME B16.5 / API 6A |

| Size Range | 2 1/16” to 4 1/16” |

| Pressure Classes | 2000 – 10,000 PSI |

| ASME Class | 150 -1500 |

| Product Spec Level | PSL 1, 2, 3, 3G & 4 |

| Materials | 4130 / 410 / A487 4C / CA15 / CF8M / Duplex / Super Duplex / Inconel |

| Trims | API Class AA ‐ HH |

| Seats | TCC coated |

| Ends | Flanged / Welded |

|

Features |

· Bi-directional in-line bubble-tight seal independent of line pressure

· Multiple external bubble-tight seals independent of line pressure. · Direct mechanical three-point adjustment independent of line pressure · Independent travel stops · Full encapsulation and retention of all leading edges of PTFE sleeve and top seal components. · Full lip at port openings protects PTFE sleeve. · Contoured waterway ensures minimum flow turbulence characteristic. · No body cavities to entrap flow media. |